Summary

- Profile Type

- Technology offer

- POD Reference

- TOAT20231213024

- Term of Validity

- 13 December 2023 - 12 December 2024

- Company's Country

- Austria

- Type of partnership

- Research and development cooperation agreementCommercial agreement with technical assistance

- Targeted Countries

- All countries

Contact the EEN partner nearest to you for more information.

Find my local partner

General information

- Short Summary

- An Austrian SME is marketing its modified TIG welding process, enabling automated mass applications, worldwide. It is highly efficient for thin sheet metal applications (0.3-3 mm; steel, aluminium, material combinations, etc.). It is spatter-free and saves costs by reduction of filler metal, gas consumption and downtime. As a one-stop shop, the SME offers customised solutions for a wide range of applications (commercial agreement with technical assistance, technical/research cooperation sought)

- Full Description

-

Tungsten inert gas welding (TIG welding) is a modern process for joining metals. An electric arc is formed between the workpiece and an electrode made of tungsten. The filler material is fed into the arc and melted in this way. Shielding gases such as argon are used to prevent the molten material from reacting (oxidising) with the surrounding air. Particularly high seam qualities can be achieved.

A major disadvantage of TIG welding is that it has to be carried out manually due to the lack of controllability. This is demanding for the welder and is often not suitable for mass applications (automotive, household appliances) due to the low process speeds.

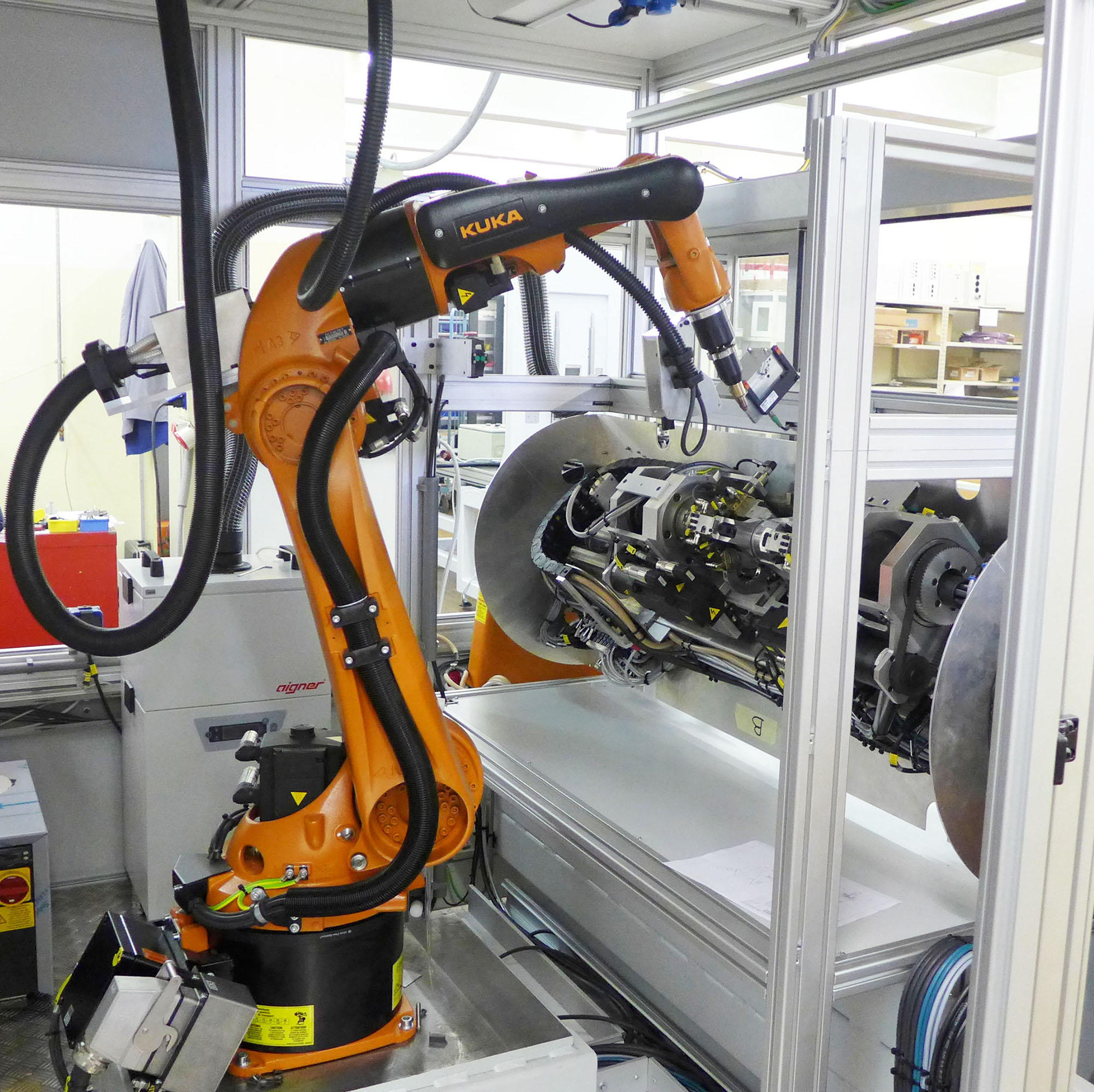

The Austrian SME (with 30 years of experience in the field of special machine construction) has successfully developed a modified TIG welding process that could be automated, thus enabling mass applications.

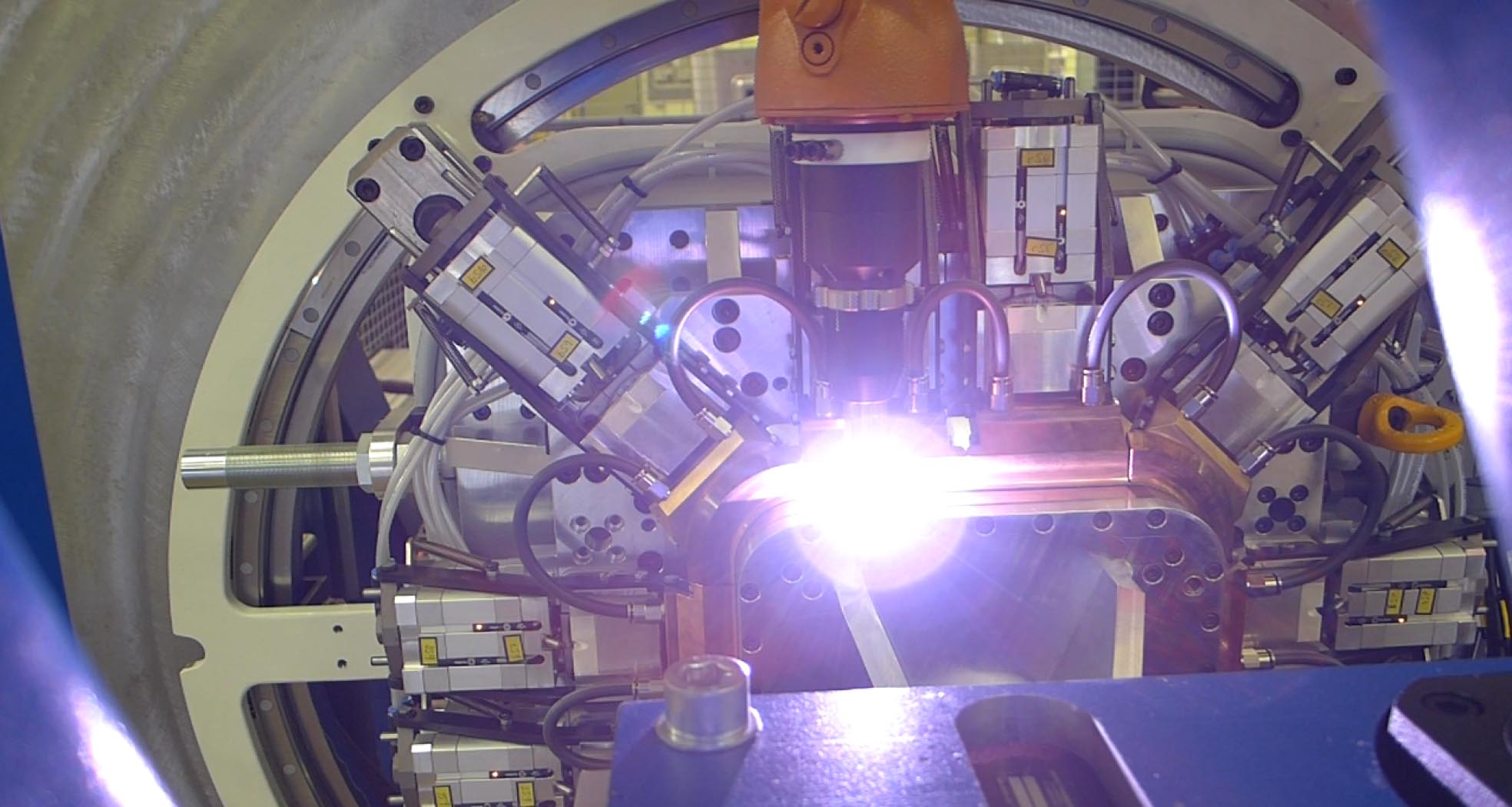

Compared to conventional TIG processes, the electrode tip is located outside the nozzle, which means that the arc is ignited outside a jet-optimised nozzle. This enables a focused arc with a higher power density and higher effective temperatures on the workpiece while minimising the heat-affected zone and reducing the thermal load on the nozzle. This leads to:

- automated process due to high controllability

- Increased productivity (higher welding speed and greater penetration depth)

- highest weld seam quality thanks to precise heat input and minimal distortion; no post-processing of the weld seam is necessary thanks to the spatter-free process;

- greatly increased nozzle service life due to reduced wear and material ageing

The internal geometry of the nozzle has been designed specifically to optimise the flow conditions and change the arc shape. This also reduces gas consumption (argon) and thus the variable process costs.

In addition, a pneumatic cathode clamping system was developed for the fastest automatic cathode change. In the normal TIG process, the entire torch head or cathod has to be replaced manually due to wear. The process then has to be stopped for a few minutes each time. The automatic changer does this in just a few seconds. In addition, short cathodes grinded on both sides can be used.

The plasma torches are manufactured by the Austrian SME itself and therefore the arc shape (nozzle geometry) can be adjusted to the joining concept (wide, narrow, rotating, etc.). This enables customised applications. The new process can be implemented inline (in existing systems) or via complete systems with different degrees of automation depending on customer requirements.

Different equipment for various applications have already been sold worldwide.

The process is suitable for joining thin sheets of steel, stainless steel, galvanised steel, aluminium (with or without alternating current) and many complex material combinations. Typical market sectors are white goods, small appliances, automotive, (public) transport, e-mobility, electronics industry, etc.

Technical details:

- sheet thicknesses: 0.3 - 3 mm

- welding speeds: up to 3 m/min

- Argon (mixtures): 5-8 l/min (no additional shielding gas required)

- energy density: 10 to the power of 6 W/cm² with cathode diameter of 3.2 mm; 10 A - 300 A welding current

- when using filler materials: significant reduction (5 times less compared to metal active gas welding)

- automatic cathode changer: < 15 sec cathode change; 24 change cycles

The Austrian company is mainly looking for industrial partners in the above mentioned fields to buy the novel technology for their products or processes. It offers technical assistance for installation and operation (commercial agreement with technical assistance), adaptations to specific requirements (technical cooperation) and conjoint development of new applications (technical/research cooperation). - Advantages and Innovations

-

Advantages compared to conventional TIG processes:

- automation possible

- increased productivity (higher welding speed and greater penetration depth) and therefore mass applications possible

- highly efficient for thin sheet metal applications (2D or 3D components) of 0.3 to 3 mm thickness

- spatter-free process and therefore no reworking of the weld seam necessary; highly suitable for inline quality control (no weld spatter)

- higher efficiency (up to 80%) compared to comparable TIG processes (70%)

- lower process costs due to:

- Argon consumption is only 5-8 l/min (approx. 50% reduction)

- in most cases, no filler metal is required (filler metals are often expensive and difficult to supply in small quantities); if required => the quantity is significantly reduced.

- greatly increased nozzle service life

- reduced downtime when wear parts need to be replaced thanks to automatic cathode changer with cathode magazine and short cathodes grinded on both sides

Advantages compared to laser welding:

- high gap bridging capability: up to 0.4 mm for sheet steel or up to 0.2 mm for sheet aluminium; laser welding requires a gap of 0 mm, i.e. the sheets must be positioned exactly without a gap => great effort needed!

- lower acquisition costs and safety requirements: laser sources, optics etc. are very expensive for laser welding.

- higher efficiency (up to 80%) compared to laser welding (40-60%)

General advantages:

- highest weld seam quality; reproducible welding process

- slim torch design for optimum accessibility

- customised solutions for a wide range of applications (joining technology, additive manufacturing)

- one-stop shop: from the idea to the system, including peripheral devices (automatic cathode changer, seam tracking system, etc.), automation

- test welding to find the right welding process

- sustainable process by low energy consumption and avoiding welding consumables (e.g. aluminium) - Stage of Development

- Already on the market

- Sustainable Development Goals

- Goal 9: Industry, Innovation and InfrastructureGoal 13: Climate Action

Partner Sought

- Expected Role of a Partner

-

Specific area of activity of the Partner:

- car manufacturers and automotive suppliers (for transport, public transport, e-mobility)

- manufacturers and suppliers of white goods (household appliances)

- manufacturers in the electronics industry

- universities and research institutes working in the field of welding technology and additive manufacturing

Some examples and latest applications:

- white goods (washing machine, tumble dryer, refrigerator and freezer, dishwasher, etc.): welding of control elements, electromechanical components, frame elements, stainless steel housings etc.

- automotive: welding of shift forks and shock absorbers; welding of resonators (turbochargers): 2 stainless thin sheets with inlaid plastic element can be welded without damaging the plastic;

- automotive: it can also be used for soldering 3D sheet metal components: e.g. roof seams on vehicles or water drainage on boot lids (galvanised body panels)

- eMobility: energy backbone (rigid aluminium flat conductors for energy distribution in cars): welding of pure aluminium (Direct current process)

Task to be performed by the Partner:

- commercial agreement with technical assistance: industrial partners willing to buy the novel system for their process or product development; the Austrian company provides training, full technical support and expertise for specific application cases to the partner;

- technical cooperation agreement: the technology can be customized according to the specific requirements of potential partners;

- technical cooperation agreement: in-house welding application development according to the specific requirements of potential partners; sampling and test welds are possible

- research cooperation agreement: the Austrian company is open to engage in the development of new welding applications together with potential industrial or R&D-partners in the framework of funded European research programmes; - Type and Size of Partner

- UniversitySME 50 - 249R&D InstitutionSME 11-49SME <=10Big company

- Type of partnership

- Research and development cooperation agreementCommercial agreement with technical assistance

Call details

- Coordinator required

-

Yes

Dissemination

- Technology keywords

- 01001001 - Automation, Robotics Control Systems03010 - Household Goods & Appliances02007010 - Metals and Alloys02009002 - Hybrid and Electric Vehicles02002008 - Jointing (soldering, welding, sticking)

- Market keywords

- 09001005 - Motor vehicles, transportation equipment and parts09004002 - Office furniture and other professional furnishings08003001 - Machine tools, other metal working equipment (excl. numeric control)08002004 - Robotics07004003 - Home furnishing and housewares

- Sector Groups Involved

- ElectronicsMobility - Transport - Automotive

- Targeted countries

- All countries